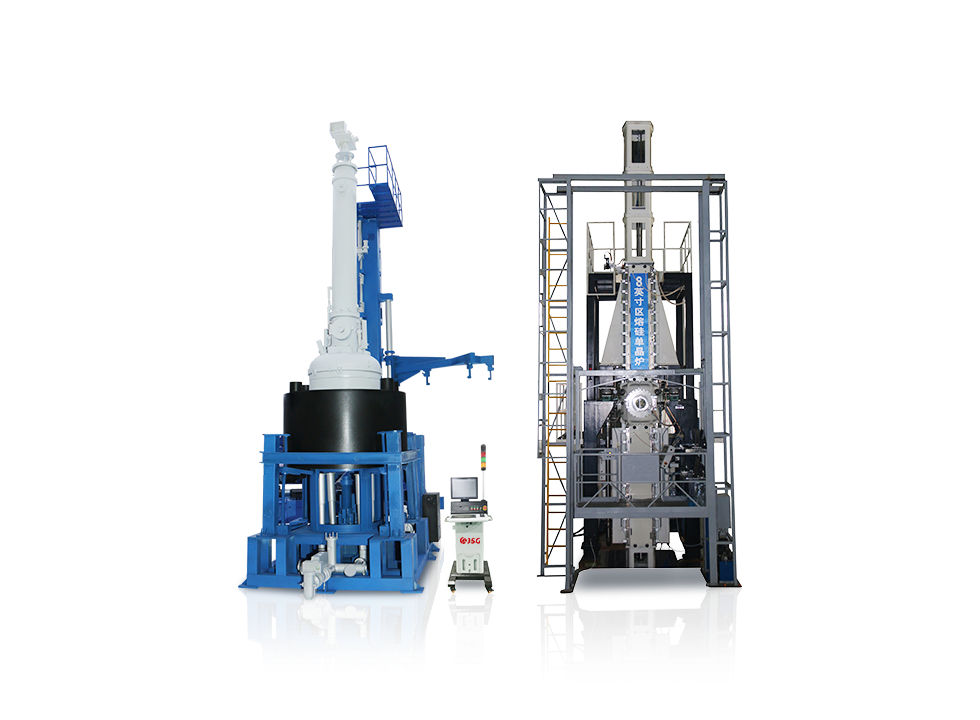

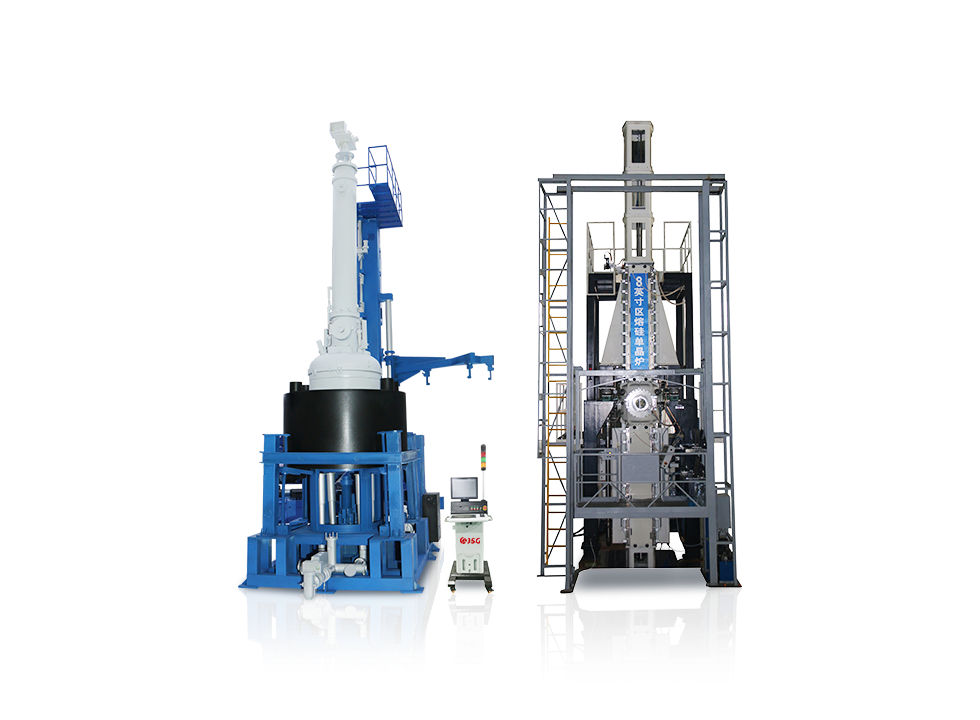

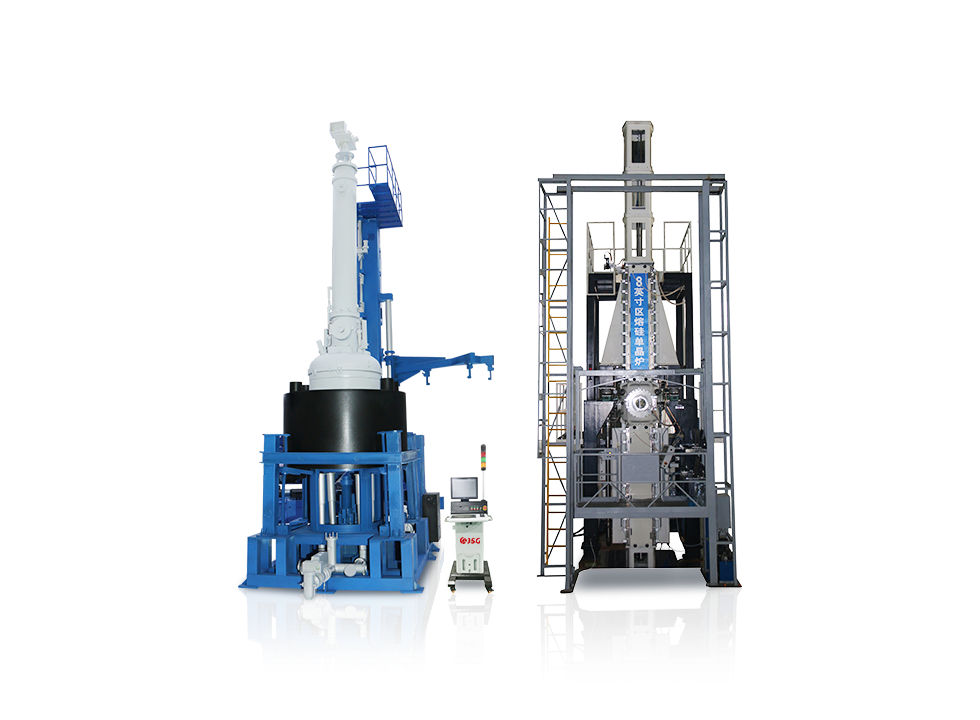

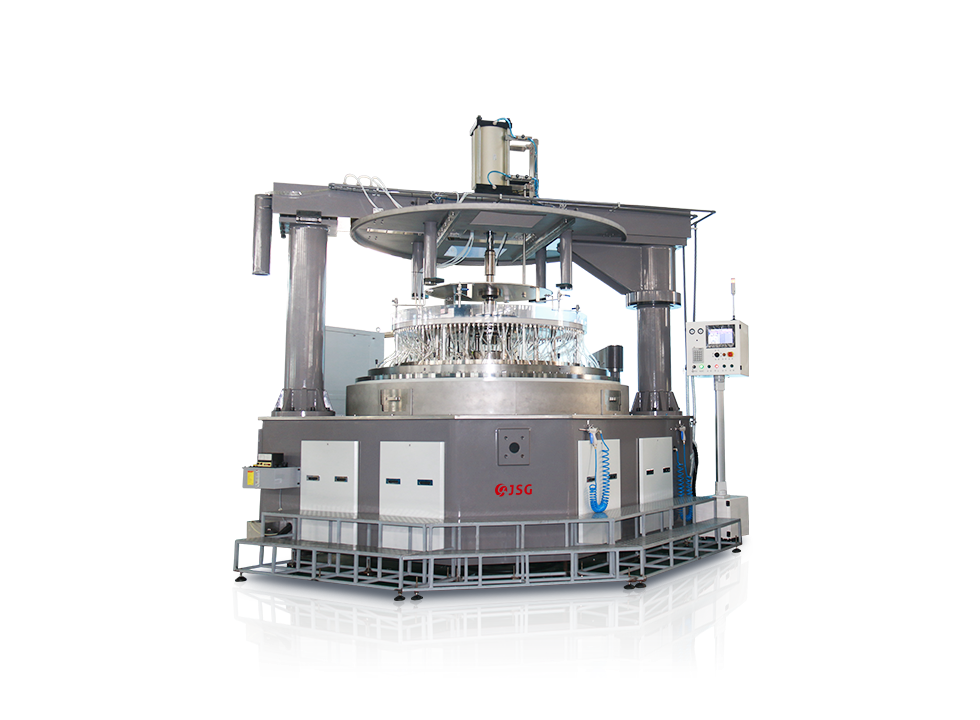

Silicon Growth Furnace

The silicon growth furnace developed by JSG can meet the needs of large-size crystal growth, taking the lead in both technology and scale

Roller

JSG has launched special processing machines for cylindrical rolling & grinding, which can process silicon ingots with diameters of 8 inches and 12 inches, featuring high processing precision, high degree of automation and strong stability

Cropper

JSG has developed special processing machines for silicon ingot cropping, which can process silicon ingots with diameters of 8 inches and 12 inches, take samples, and crop cone heads and crystal segments, featuring high processing efficiency, low customer use cost, and high degree of automation

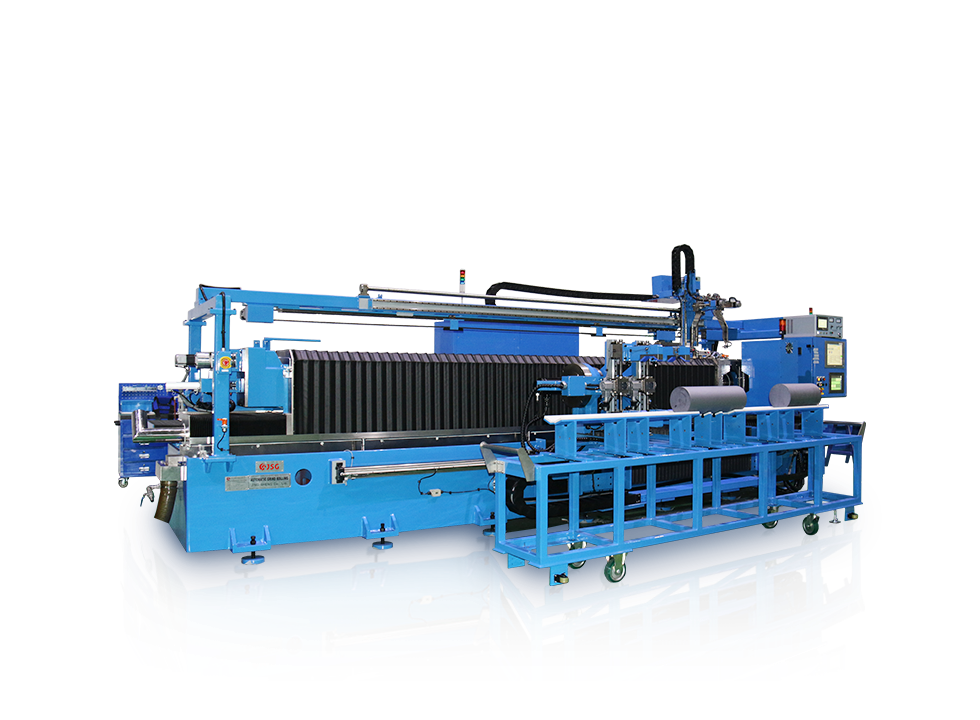

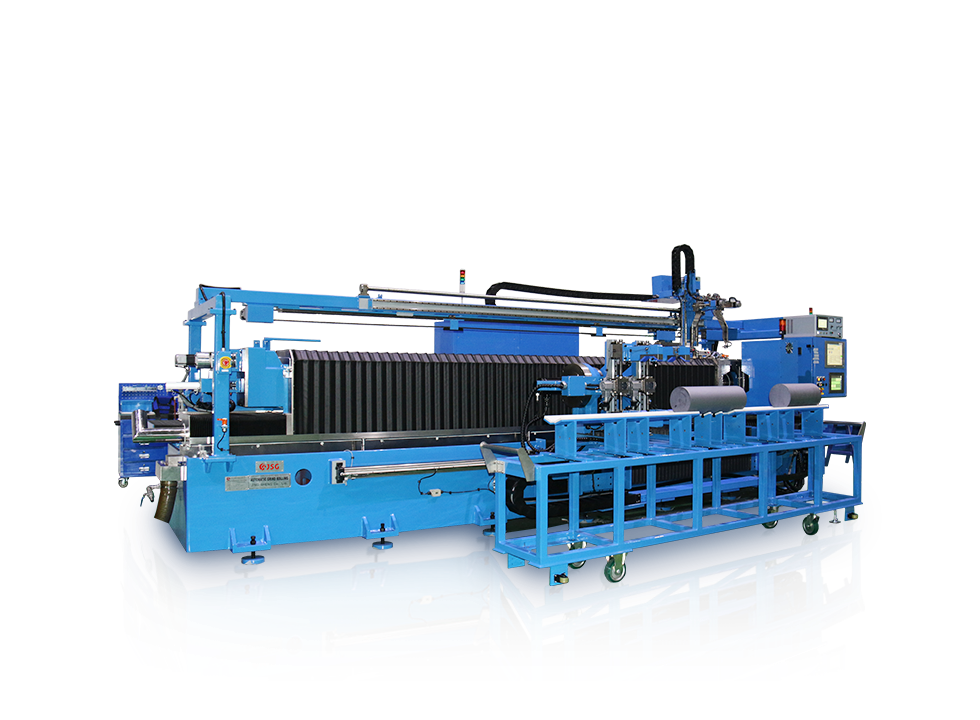

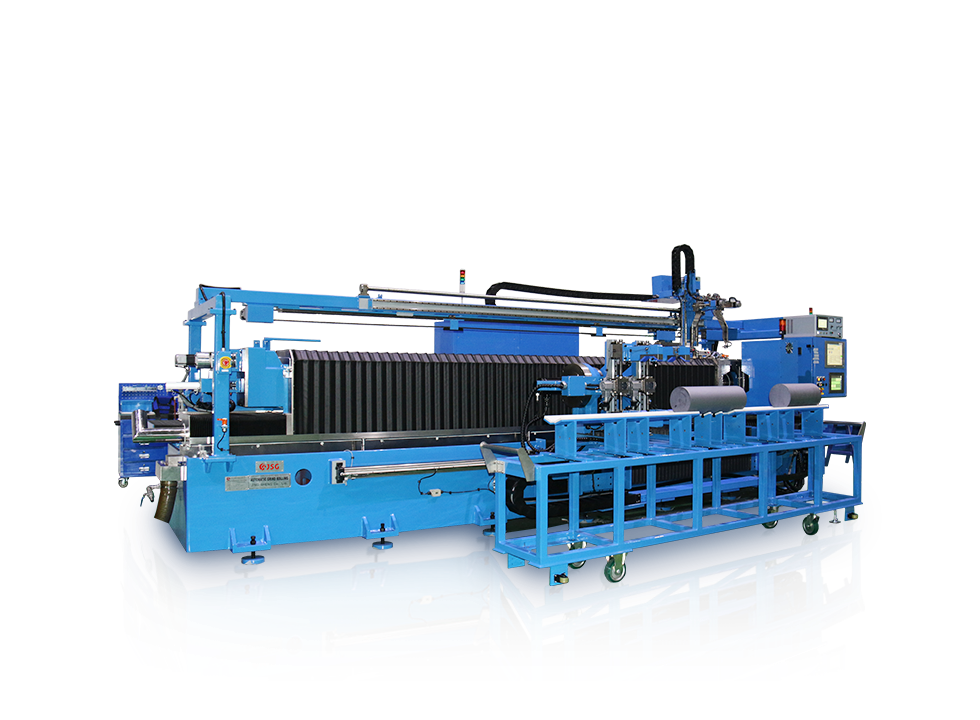

Wire Slicer

JSG has developed crystal slicers for photovoltaic silicon, semiconductor silicon, and sapphire, which are highly qualified for slicing materials with specifications of 4 to 12 inches

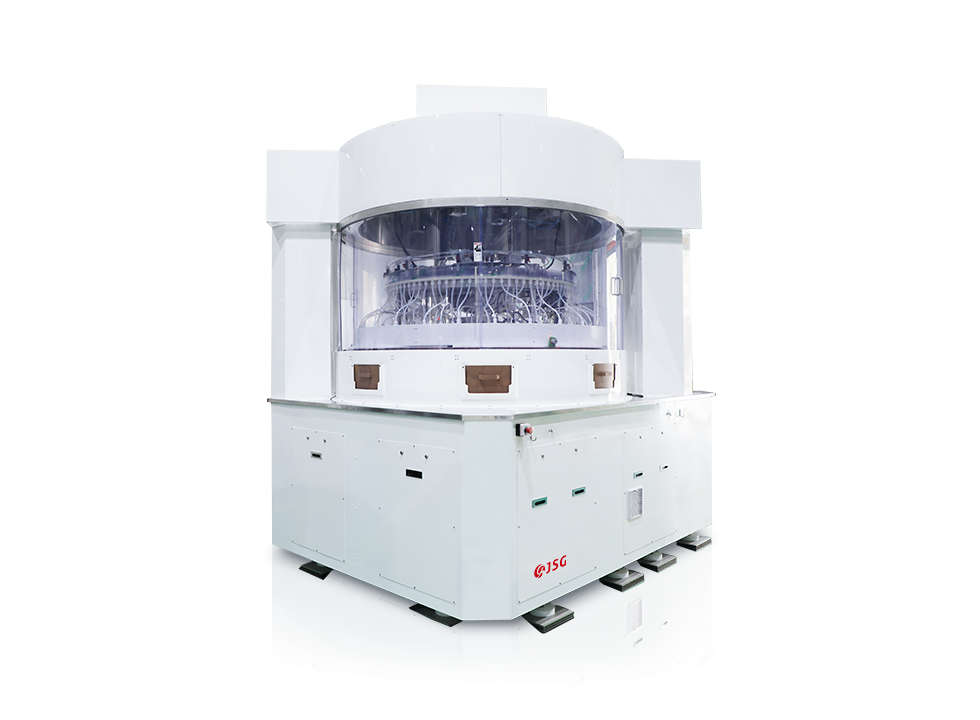

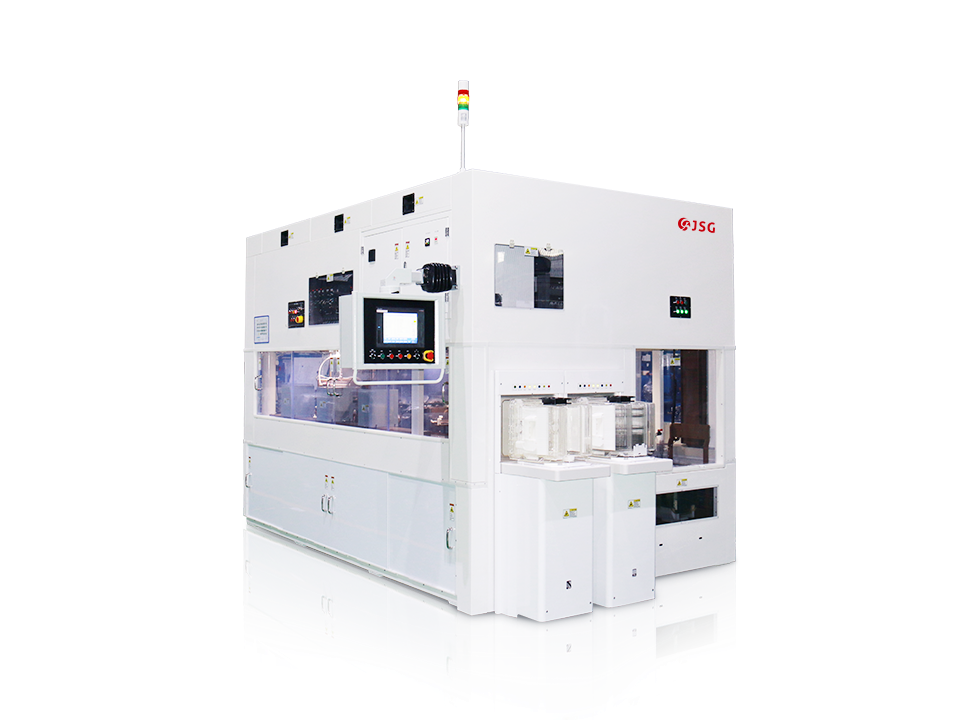

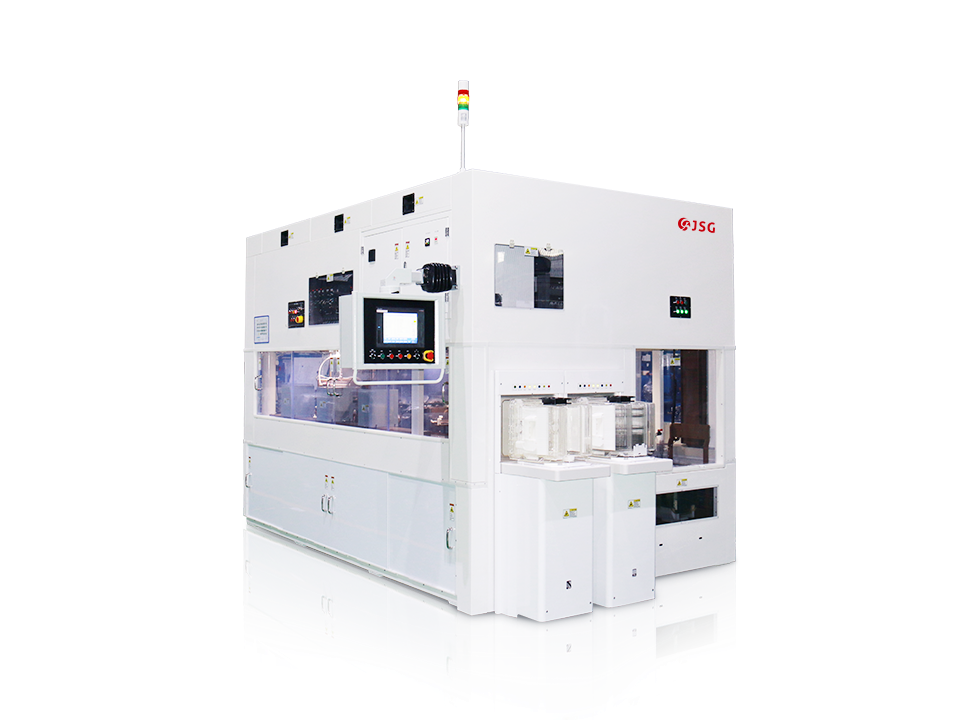

Chamfering Machine

The semiconductor-level high-precision chamfering machine developed by JSG can process 8-inch and 12-inch mono crystal silicon wafers, featuring high processing efficiency, high precision and strong stability

Grinder

JSG has developed double-sided precision grinders for semiconductor-grade mono crystal silicon wafers, which can process 8-inch and 12-inch mono crystal silicon wafers, featuring high processing efficiency and high precision

Thinning Machine

The grinder developed by JSG is mainly used for single-sided grinding of semiconductor mono crystal silicon wafers, and can also be applied to single-sided high-precision grinding of other crisp and hard materials

Edge Polisher

JSG has developed polishers applied to the edge of semiconductor mono silicon wafers, which can process 8-inch and 12-inch mono silicon wafers, filling the gap in domestic 12-inch edge polishers and realizing the substitution of imported equipment

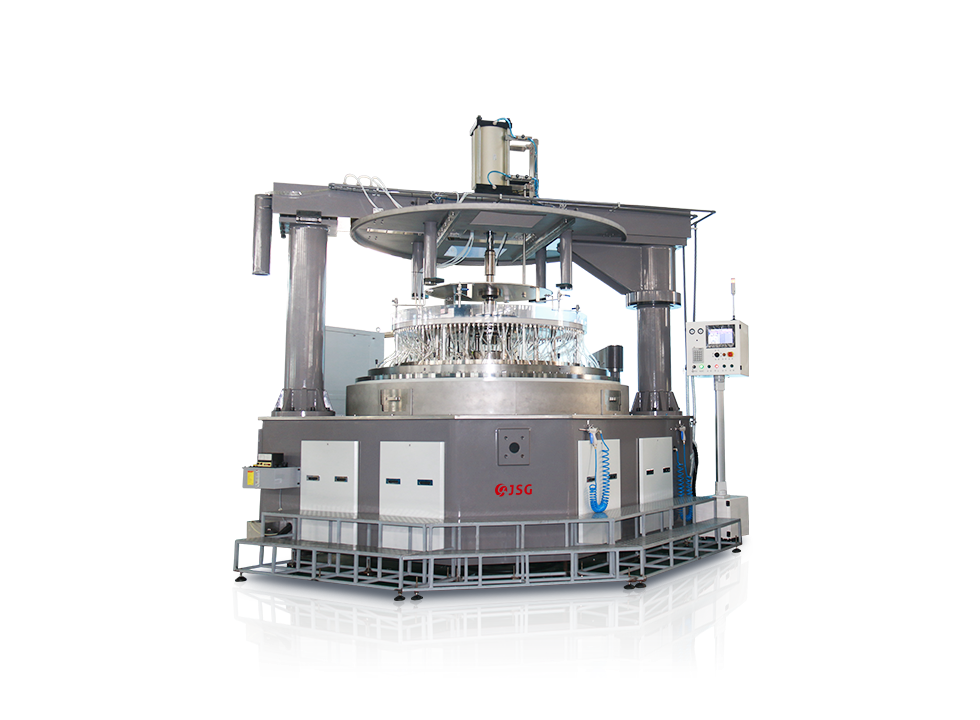

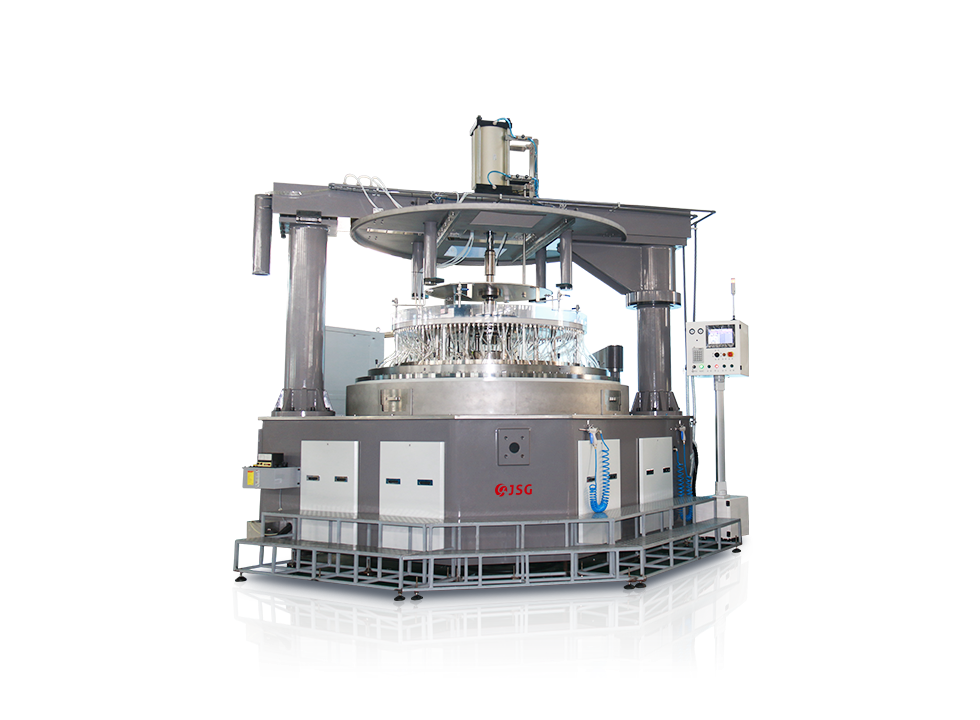

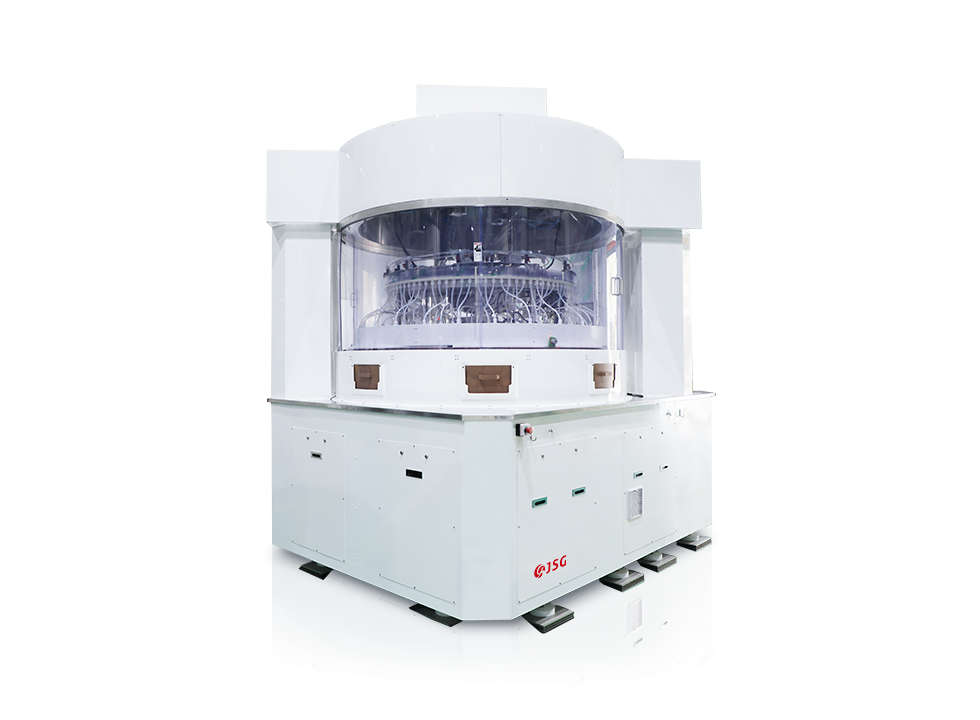

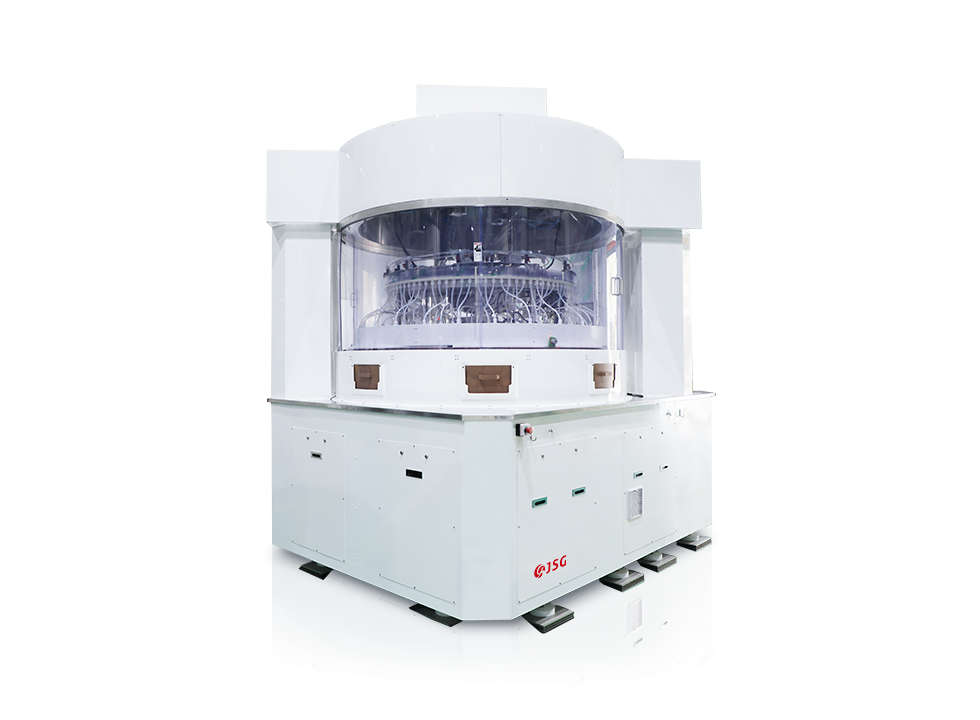

Double-sided Polisher

JSG has developed grinders and polishers for silicon carbide, semiconductor silicon, and sapphire, which is highly qualified for grinding and polishing materials with specifications of 6 to 12 inches, featuring high production capacity, high precision and high stability

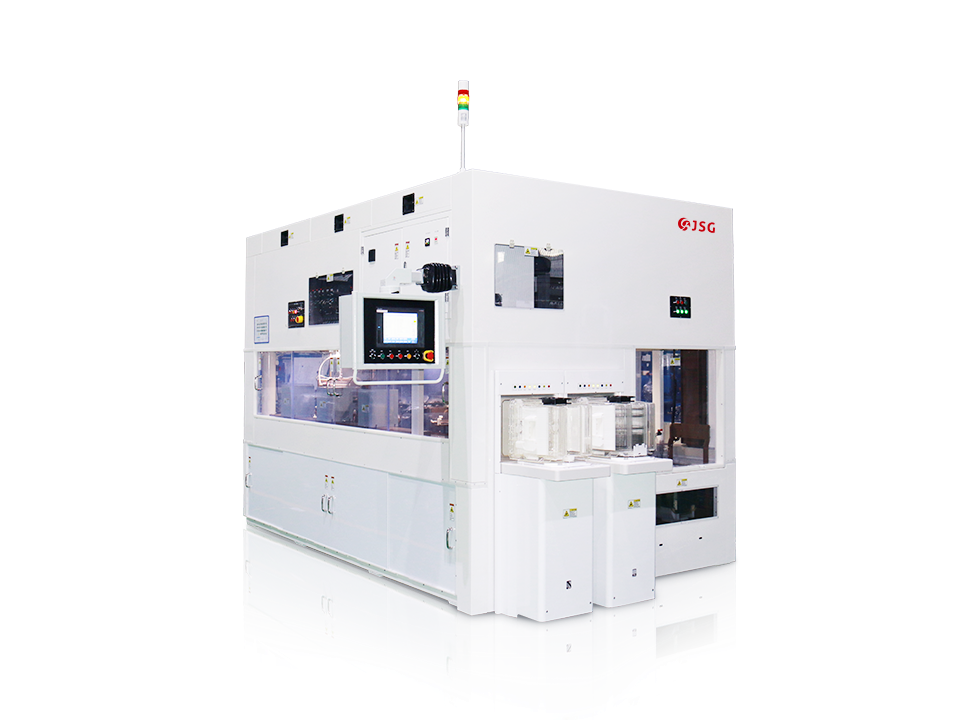

Final Polisher

JSG has developed final polishers for 12-inch silicon wafers and realized localized supporting applications to replace imported equipment. The device features high degree of automation and stability, and the flatness of processed products proves good

8-inch Polishing Wire

The 8-inch polishing wire developed by JSG can replace imported equipment, featuring high degree of automation and good stability. It can be connected to various forms of automatic loading and unloading methods to meet customized needs of customers

Semiconductor Materials and Equipment (Some Products)

There is a full chain of equipment from crystal growth to processing of 8-12-inch semiconductor silicon wafers